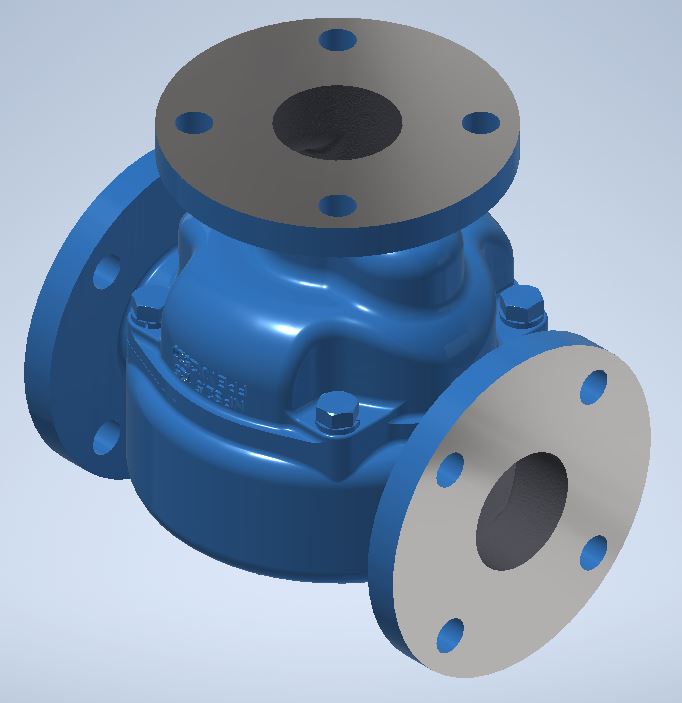

Model 2510

Thermostatic Control Valves

- Connection Size: 2 1/2" FLANGES

- Dimension: DN65

- Three-way thermostatic control valve

- Wide range of temperatures

- Replaceable, non-adjustable, tamper-proof thermostats

- Self-contained unit

- Compact, heavy duty, rugged construction

- Operate in any orientation

Compact and Reliable Temperature Control

Fluid Power Energy (FPE) thermostatic valves utilize the principle of expanding wax. As the fluid temperature increases, the wax transforms from a solid to a liquid state. This expansion causes the thermostat sleeve to stroke thereby controlling the direction of fluid flow to achieve the required operation.

All FPE valves can be used for diverting or mixing applications without modification of the valve assembly. FPE thermostatic valves are factory set to predetermined set-point temperatures, so no field adjustments are necessary. Simply connect the valve to your system and walk away.

Contact an FPE representative today to see how our thermostatic control valves can enhance your application. Contact Us